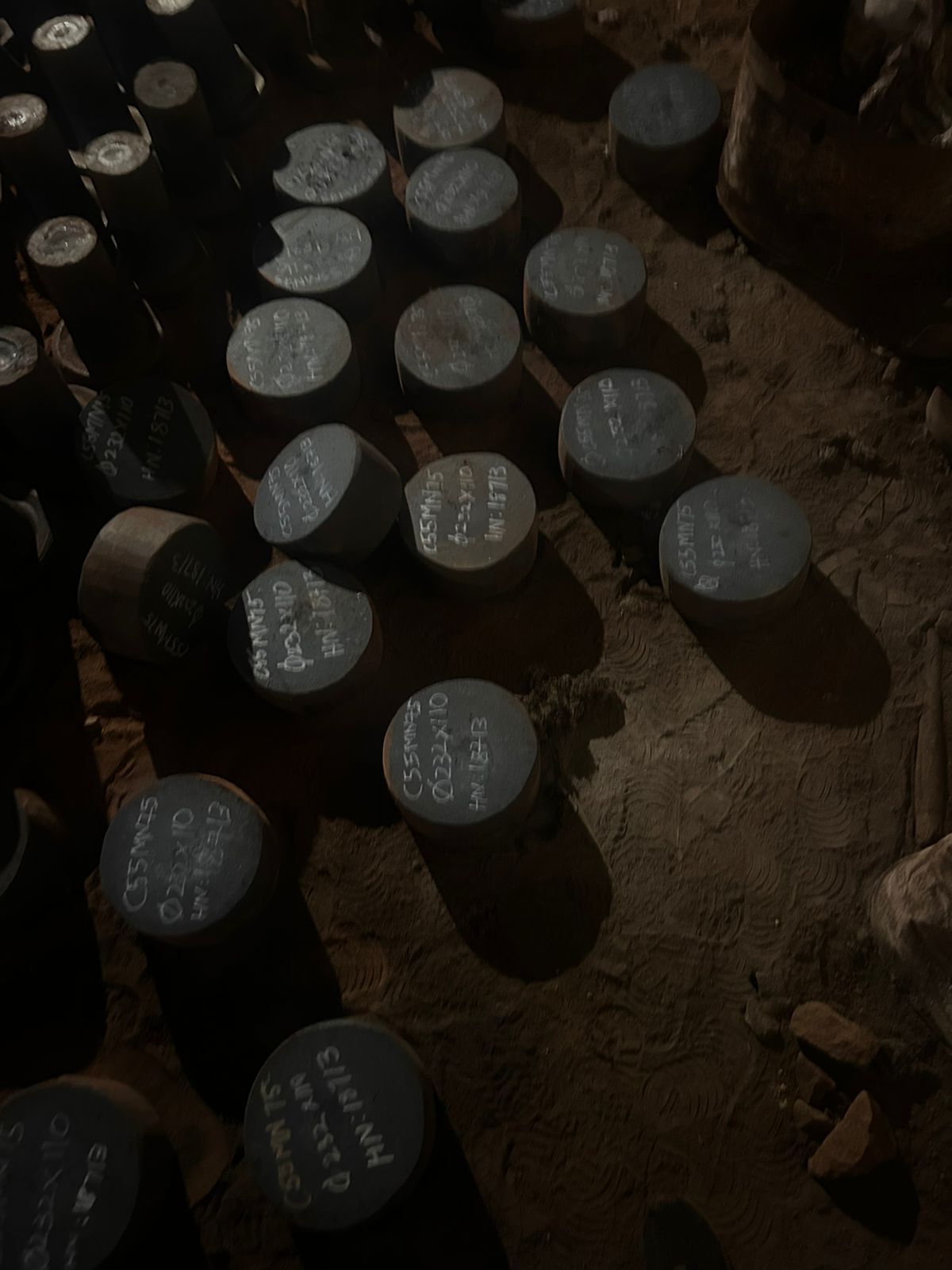

LARGE SIZE LATHE CNC CHUCK BODY

LARGE SIZE LATHE CNC CHUCK BODY Specification

- Hardness

- Hard

- Product Type

- Forged Products

- Material

- Steel

- Application

- Machine Parts

- Color

- Silver

LARGE SIZE LATHE CNC CHUCK BODY Trade Information

- Minimum Order Quantity

- 100 Number

- Supply Ability

- 5000 Per Month

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Other Forging Products Category

DTH Hammer Control Tube Forgings

Price 250 INR / Number

Minimum Order Quantity : 150

Process : Forged

Surface Treatment : Other, Shot Blasted, Antirust Coated

Color : Bright Steel Grey / Black

Hardness : 3842 HRC

Precision Forged Gear and Pinion

Price 500 INR / Number

Minimum Order Quantity : 150

Process : Precision Forged

Surface Treatment : Other, Phosphating, Heat Treatment, Oil Blackened

Color : Black Oxide, Metallic Grey

Hardness : 5862 HRC

Steel Valve Body and Bonnet Forgings

Price 1000 INR / Number

Minimum Order Quantity : 150

Process : Closed Die Forging

Surface Treatment : Other, Shot Blasting, Heat Treated, AntiRust Coating

Color : Metallic Grey

Hardness : 180 230 HB

Bevel Gears Precision Forging

Price 1000 INR / Number

Minimum Order Quantity : 150

Process : Precision Forging

Surface Treatment : Other, Polished, Heat Treated

Color : Metallic Grey

Hardness : 5862 HRC

Send Inquiry

Send Inquiry Send SMS

Send SMS