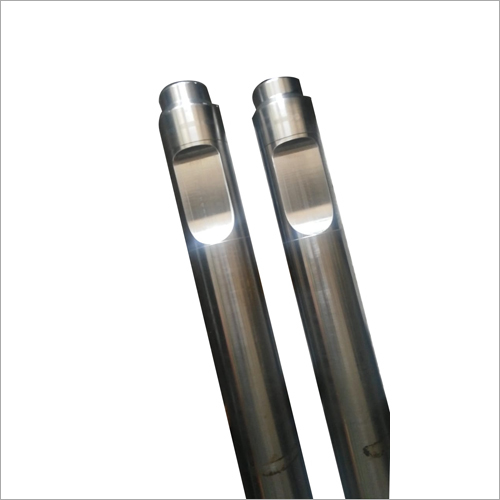

Hydraulic Rock Breaker Rod Pins

Hydraulic Rock Breaker Rod Pins Specification

- Surface Treatment

- Induction Hardened

- Hardness

- HRC 52-58

- Process

- Forging, Precision Machining

- Product Type

- Hydraulic Rock Breaker Rod Pin

- Material

- Alloy Steel

- Technology

- Heat Treatment

- Application

- Excavator Hydraulic Hammer

- Dimension (L*W*H)

- Custom Sizes Available

- Weight

- 2 kg - 5 kg (depending on size)

- Color

- Metallic Grey

- Service Life

- Long-lasting, Wear Resistant

- Quality Standard

- ISO Certified

- Packaging

- Wooden Case/Carton

- Usage

- Earthmoving, Mining, Construction

- Surface Finish

- Smooth

- Tensile Strength

- >1000 MPa

- OEM Support

- Available

- Yield Strength

- >900 MPa

- Corrosion Resistance

- Yes

- Compatibility

- Fits various brand models

Hydraulic Rock Breaker Rod Pins Trade Information

- Minimum Order Quantity

- 100 Number

- Supply Ability

- 1000 Per Day

- Delivery Time

- 4 Week

About Hydraulic Rock Breaker Rod Pins

Hydraulic Rock Breaker Rod Pins, hydraulic breaker rod pinsHydraulic Rock Breaker Rod Pins, hydraulic breaker rod pinsHydraulic Rock Breaker Rod Pins, hydraulic breaker rod pinsPrecision Engineering for Enhanced Performance

Every rod pin is crafted through forging, advanced heat treatment, and precision machining to achieve high strength and exceptional wear resistance. Induction hardening gives them a tough, durable surface-ideal for demanding earthmoving, mining, and construction jobs. Our robust manufacturing ensures the rod pins withstand rigorous working conditions, extending equipment service life.

Adaptable Compatibility for Multiple Brands

Designed to fit various hydraulic breaker brand models, our rod pins offer broad compatibility and flexibility. Whether you operate excavators from major manufacturers or require a custom fit, we provide sizes tailored to your equipment's exact requirements. The OEM support guarantees a precise match for seamless integration with your machinery.

Committed to Quality and Longevity

Our pins are produced from high-grade alloy steel and treated for optimal hardness and corrosion resistance. Each product is thoroughly tested and ISO certified for quality assurance. This commitment to quality translates into long-lasting, dependable rod pins that minimize downtime and maintenance costs for your operations.

FAQ's of Hydraulic Rock Breaker Rod Pins:

Q: How do you ensure the durability and wear resistance of your hydraulic rock breaker rod pins?

A: Our rod pins undergo a forging process followed by induction hardening and precise heat treatment. These processes increase surface hardness (HRC 52-58), making the pins highly resistant to wear and suitable for continuous use in tough mining and construction environments.Q: What is the compatibility range for these rod pins?

A: These pins are designed to fit a variety of hydraulic breaker and excavator brands. We offer custom sizing to match your specific model, ensuring seamless integration regardless of equipment make.Q: When should the rod pins be replaced in hydraulic rock breakers?

A: It is recommended to inspect rod pins periodically for signs of wear, deformation, or excessive looseness. Replacement should occur if there is visible damage or if performance drops, to prevent equipment failure and ensure safety.Q: Where are your hydraulic rock breaker rod pins manufactured and exported from?

A: We manufacture and supply our rod pins in India, exporting globally to clients seeking robust solutions for earthmoving, mining, and construction machinery.Q: What processes and technologies are used during manufacturing?

A: The manufacturing includes forging, heat treatment, induction hardening, precision machining, and advanced surface treatments, all monitored to maintain strict ISO-certified standards for quality and durability.Q: How are the rod pins packaged for delivery?

A: Rod pins are securely packaged in wooden cases or cartons to protect against damage during transit. This packaging ensures safe delivery whether shipped locally or internationally.Q: What are the key benefits of using your hydraulic rock breaker rod pins?

A: Our rod pins offer high strength, long-lasting wear resistance, corrosion protection, broad compatibility, and enhanced equipment uptime, leading to reduced maintenance costs and extended service life in demanding applications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Rock Breaker Parts Category

Hydraulic Rock Breaker Through Rods

Price 4500 INR / Piece

Minimum Order Quantity : 150 Pieces

Product Type : Forged Products

Application : Other

Material : Other

Technology : Forging

Rock Breaker Chisels

Price 25000 INR / Piece

Minimum Order Quantity : 150 Pieces

Product Type : Forged Products

Application : Other

Material : Other

Technology : Forging

Hydraulic Rock Breaker Bushes

Price 5500 INR / Piece

Minimum Order Quantity : 100 Pieces

Product Type : Forged Products

Application : Other

Material : Other

Technology : Forging

Send Inquiry

Send Inquiry Send SMS

Send SMS