Back to top

Download Brochure

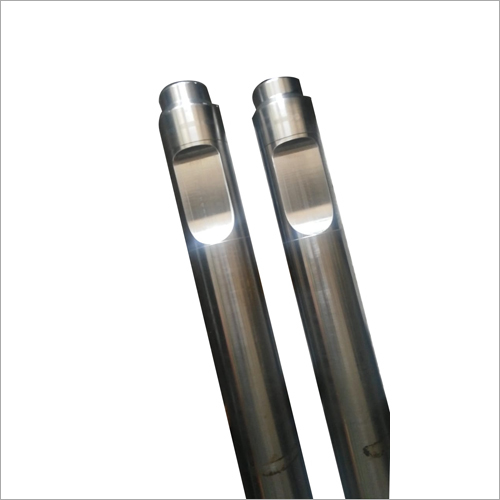

Your Most Reliable & Resourceful Partner For Availing Chuck Jaw Carriers, Tractor Shafts, Ring Forgings, Hydraulic Rock Breaker Bushes, Lathe CNC Lathe Spindles, Lathe Chuck Jaws & More.

About Us

We, Sai Charan Forgings are rising and thriving in the Indian industry by providing advanced forging solutions. Being a manufacturer, we are determined to provide premium grade materials of FERROUS, like carbon steel , alloy steel, case hardening, spring steels & NON FERROUS like aluminium, copper, stainless steels products to our customers including both standard as well as customised ones to match their exact requirements & steel expectations. Our offered assortment for them is ranging from Tractor Shafts, Chuck Jaw Carriers, Hydraulic Rock Breaker Bushes, Ring Forgings, Lathe Chuck Jaws, Lathe & CNC Spindles to various more items. Our open forgings can efficiently handle components up to 1000 kgs of individual weight, whereas our closed die forgings can bear weight up to about 70 kgs. The ring forgings can be used on products with up to 1500 mm diameter. Also, we can fulfill the requirements of customers for certain products with piece weight of 10 tones with support of our associates.

Download Brochure

Send Inquiry

Send Inquiry Send SMS

Send SMS